Press release

An eternal life for load securing devices: allsafe presents a process for saving money with sustainability and high availability.

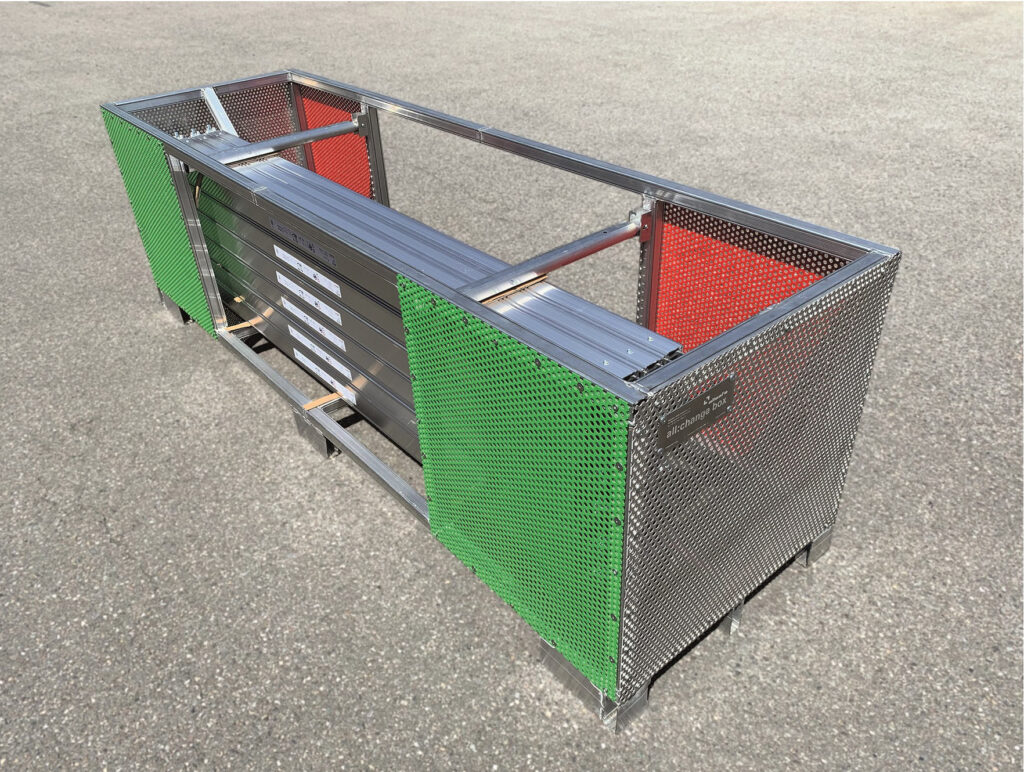

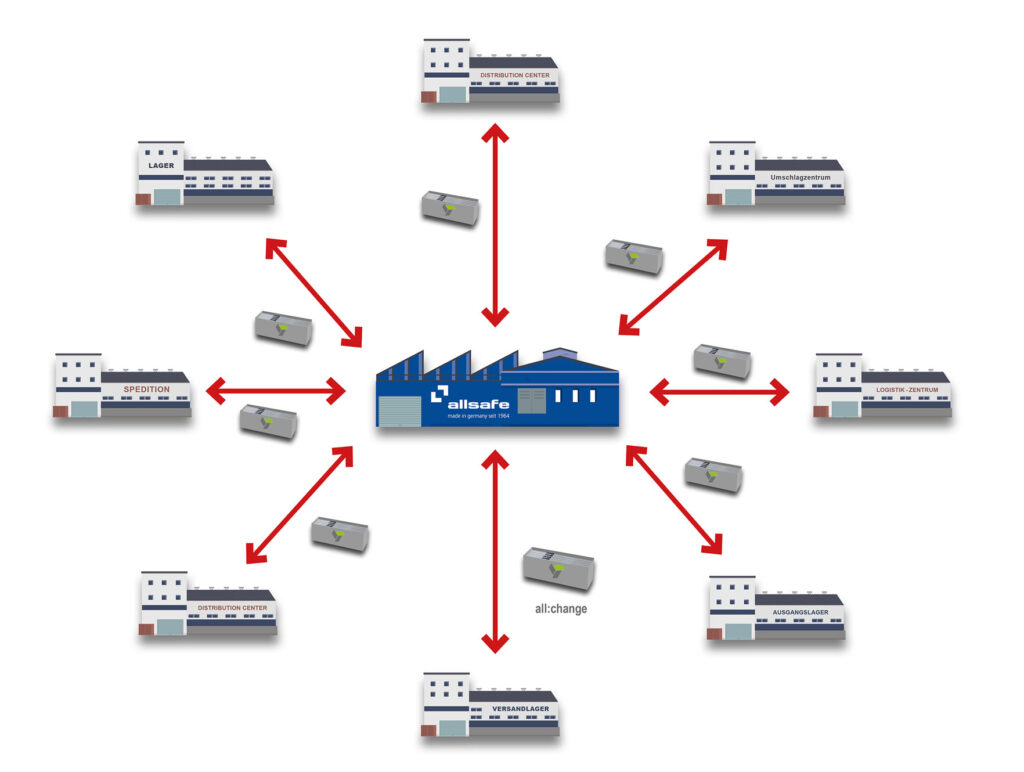

Engen, September 2021 - The Engen-based load securing specialist allsafe presents its new all:change offer at NUFAM. With this, used, worn or damaged load restraints are quickly made ready for use again, and costs and CO2 emissions are reduced.

Almost everywhere trucks are in use, there is a corner where old bars and beams for securing loads or for double-deck loading lie around. The parts are often too good to dispose of. But they cannot be used properly either because they are more or less defective.

As a well-known manufacturer of such load securing products, allsafe has now developed an offer for this, with which it apparently wants to compete with itself: "We offer to pick up such locking bars and double deck beams, check them, repair them and deliver them back to the customer with a fresh UVV sticker," is how managing director Jens Laufer describes the new offer, "and at a fixed price." If a product is no longer repairable, allsafe will exchange it for a refurbished or new part - at the repair price. "This is about as simple as using the good old deposit bottle - and always cheaper than buying a new product", Laufer sums up the customer benefit. According to its own information, allsafe has already been able to win several large forwarding companies as customers for this innovative service in the run-up to NUFAM.

Calculation example for CO2 savings:

- One plywood or double-deck beam contains approx. 7 kg of aluminium.

- The production of one kilogramme of aluminium generates around 7 kg of CO2.

- This results in around 49 kg of CO2 per product.

If the product is repaired, in our experience only about 2-3 kg of product are defective, 4-5 kg of product can be reused. This saves over 50 % (= approx. 30 kg) CO2 in the use of load securing as well as resources and protects the environment through significantly lower primary aluminium requirements.

"After a break of more than a year from the trade fair, NUFAM offers us the opportunity to present our sustainability innovations, which we have worked on during this time, live to a broad professional audience and to talk to them about them."

Matthias König, Product Manager, allsafe GmbH & Co. KG .